Monthly Archives: January 2014

If you want to build the natural way

The idea of building with natural materials is great, but the materials face a major limitation. Being part of the ecological life cycle, they tend to wither by wear and tear; underperform if defective materials are used; and deteriorate much faster than manufactured materials if problems are ignored. As such, with the technical and industrial capacity we have researched during the recent centuries, we have started processing them with chemicals, coatings and additives or even replacing them with artificial materials.

The idea of building with natural materials is great, but the materials face a major limitation. Being part of the ecological life cycle, they tend to wither by wear and tear; underperform if defective materials are used; and deteriorate much faster than manufactured materials if problems are ignored. As such, with the technical and industrial capacity we have researched during the recent centuries, we have started processing them with chemicals, coatings and additives or even replacing them with artificial materials.

By this, while some of the limitations of natural materials have been overcome to our advantage, we have landed up with huge resource and energy consumption, endangering our civilisation. Hence, the urgent need to return to building with nature.

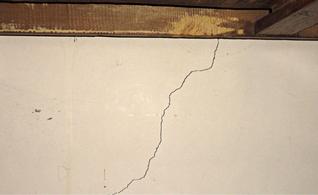

By watching the performance of structures and materials, one can ensure better strength and durability of any building, especially so with eco-friendly architecture. Letting the walls get direct rain and wind is among the major concerns, where water may penetrate into the joints, space between composite walls or wall cavities. Cracks and surface dampness are the easy indicators.

All possible points of water ingress should be sealed. Conventional wall plastering may have no structural strength, but it seals the walls. The weight of the structure and regular watering of plants result in changing soil characteristics, often leading to unequal settlements. Cracks running diagonally and sometimes even horizontally indicate it, which needs early checking by engineers.

What is adequate

Most eco-friendly houses are small structures, not higher than ground and two more floors. Load bearing walls are more than adequate for them, with no real need for RCC column and beam. Nowadays, RCC frame structures are employed blindly everywhere, so most engineers and masons have lost the knowledge of masonry walls. Out of ignorance or otherwise, if the walls are overloaded, they may compress and cracks.

Also, heavy loads of beams, upper floor walls and such others should not be placed directly upon a small area, technically called point loading. Engineers should be consulted to ensure that the loads are distributed, lest the walls crack.

Under a flat roof, the load bearing walls perform better. In case of sloping and curved roofs, the weight of roof will try pushing the wall at the lower side, hence traditionally there used to be a wall plate beam or timber member on top of the wall. This crucial member, if forgotten in a masonry wall, will put the wall under stress and it may crack, bulge or lean outside.

Walls may otherwise face the same fate if the masonry blocks such as brick, hollow clay blocks or stabilised mud blocks are improperly made, with inadequate density, porosity, strength or curing. In case of doubt, it is safer to get them tested in advance.

As it can be seen, much depends upon quality and professionalism to make a good building, be it conventional or alternative.

Tracking cracks in structures

What discourages people from building with natural materials? Why are there very few buildings using them, despite people knowing much about the cost and performance advantages of mud, stone, bricks, wood, bamboo and clay? Eco-friendly architecture nurtured human settlements for thousands of years, yet our generation seems to be discarding the idea. Are there reasons for rejection other than material scarcity or vanishing skill?

What discourages people from building with natural materials? Why are there very few buildings using them, despite people knowing much about the cost and performance advantages of mud, stone, bricks, wood, bamboo and clay? Eco-friendly architecture nurtured human settlements for thousands of years, yet our generation seems to be discarding the idea. Are there reasons for rejection other than material scarcity or vanishing skill?

Apprehensions of many kinds are among the major reasons and cracks are among the major apprehensions. All buildings crack, irrespective of them being sustainable or consuming; local or global. Expansion and shrinkage due to temperature, humidity and loading happen to all construction materials, resulting in cracks. Some could be invisible; the visible ones could be small or big; they may appear in wall or window; some may appear and disappear periodically. If so, cracks are not an inherent characteristic of sustainable buildings only built with natural materials or alternative technology. Yet, the pretext of cracks is often sighted to discourage people from constructing an eco-friendly building.

It is not easy to decipher cracks to be structurally dangerous or not. Mostly what we get to see is surface cracks in plastered walls, small angular lines in the corners of window bottoms, some narrow cracks in the edge of lintels, horizontal gaps where concrete beam touches brick wall or slab bottom, vertical cracks along concrete columns and such others, all of which are harmless. There are valid reasons such as shrinkage of material, differential wall weight around window openings, ignoring code of practice, speed of construction, lack of supervision, and non-compatibility of two materials like RCC and bricks when placed adjacent to each other. All these are commonly seen in conventional plastered buildings also.

Contrary to the common belief, in case of exposed materials, we tend to see less of cracks, with the joints absorbing and concealing them. If we try composite wall, i.e. with different materials for outside and inside, people worry that they may separate with a gap in between. This does not normally happen because of material bonding and mortar packing in between.

When wall materials like clay block or stabilised mud block end at a concrete column, they should not be touching it, but be segregated by a mortar joint, which will ensure no visible cracks.

Walls with natural materials, if very long or wide, may develop cracks following the shrinkage in volume. Hence, it is advisable to break the area by openings, lintels, concrete bands and such others to reduce the risk. Filler slabs, if laid across large spans, may develop cracks; hence need expansion joints, just like normal RCC roof. Arches and vaults tend to shrink, hence crack. All these cited cases normally do not fail structurally. Once we refinish it with crack fillers, they get covered up and the cracks will not reappear.

There are specific cracks that denote structural implications, which need to be studied in more detail, lest we may assume all cracks to be harmless.

Tackling loose soil

When the British ruled India, among the many local practices they despised was that of the construction sector. To them, ideas of our past generations appeared unprofessional, hence introduced the European systems from their land. No doubt India benefitted in numerous ways by these new systems, but unfortunately, time-tested wisdom got lost in this process. Among these casualties, systems of foundation are notable.

Different regions of India followed different methods to solve the problem of transferring the building load to the ground. There were earth consolidations, wooden piles, boulders, stone slabs, deeper external wall foundations, sand packing and many more, which appeared flimsy to the British.

They introduced the method where dressed stone or masonry blocks are laid in layers, each upper layer narrower compared to the lower one, creating the stepped appearance, popularly believed to be stronger. It requires dressing the block into neat looking sizes, lime or cement mortar, back-filling the trench and needs to start from the hard strata of earth, hence could be many feet deep into the earth. In loose soil, such foundations demand much money and effort.

A simpler and traditional practice in this direction has been to drive down small poles 4 to 6 inch diameter into the soil at every one foot distance in both the directions. A normal 3 ft. wide and 3 ft. deep foundation trench is first dug out, with the top soil still loose.

Any locally available bamboo, casuarina, forest wood or such other poles which tend to grow narrow, straight and long are chosen with the desired length with the bottom tip left blunt or slightly tapered. The whole pole is given anti-termite treatment for durability and the top part wrapped with cloths or tied with ropes to avoid it splitting due to hammering.

Each one is steadily and slowly hammered down into the loose soil till it stops moving down. Technically, this method is nothing but a pile foundation, where modern concrete piles had their predecessor in wooden piles. This ensures the bottom strata of soil is made denser and tightly packed, hence is empowered to take greater load. Upon this layer of piles, masonry foundation was laid to the full width of trench, by packing stone boulders, quarried laterite, local bricks or any other local material.

The negatives

The flip side of this system is difficulty in gauging the increased load bearing capacity, which if needed can be found out by conducting on-site pile capacity testing. If the soil is excessively dry, intermittently water logged or termite infested, additional precautions need to be taken.

The driving down of the poles, mostly done manually, should be done honestly till they reach the layer of hard soil.

Soil types vary due to percentage contents of clay, sand, black cotton, gravel, laterite and such others, hence have varied expansion, water retention and shrinkage characteristics, which need to considered.

As modern science of construction is advancing, an occasional looking back may unearth forgotten knowledge systems that are resource saving and eco-friendly.

New ideas and team spirit

In this information age, there are three kinds of building owners – those who think they know all, those who feel they have the right to know all and those who search Google hoping to know all. Behind all these, there is an attitude of not trusting the construction team, hence an attempt to learn about the process fresh and exercise it during the construction. Naturally it is getting difficult to convince people even if we are considering the routine conventional methods, while convincing and executing the alternate ideas is a real challenge.

In this information age, there are three kinds of building owners – those who think they know all, those who feel they have the right to know all and those who search Google hoping to know all. Behind all these, there is an attitude of not trusting the construction team, hence an attempt to learn about the process fresh and exercise it during the construction. Naturally it is getting difficult to convince people even if we are considering the routine conventional methods, while convincing and executing the alternate ideas is a real challenge.

The only road map is to build mutual trust and confidence within the team to stay on despite ups and downs. Up front, one should explore all the options, to avoid the feeling “that could have been done” at the end of the project. All major issues need to be resolved in advance by the owners, designers and builders to avoid ad-hoc decisions later, though minor changes can still be effected; the team should enjoy a synergy towards on site coordination; and above all everyone should be bound by an ethical passion. If we fail in this synchronization, sometimes during the construction, the blame game starts to ruin the building.

Challenge is to address the problem

Every building project faces defects, delays, hurdles, crisis and many other shortcomings. These are not special to green ideas, but if something goes wrong with the green alternate, people start blaming it all on the alternate thought itself, as if the main stream conventional buildings are all perfect. Any structure may crack and any house may leak, so the challenge is to address the problem rather than to victimize any one system.

Clarity of mind, focus on the expectations and being decisive are among the basic necessities for the smooth flow of a project. Financial transparency and honesty is virtually the foundation for any team spirit in construction industry. More than half the fall outs during the project happen over money matters, though lack of quality or undue delays can also cause the rifts between the team members.

Given the above contexts, information from the internet can not be allowed to rule a project. There are critical differences between learning the skill by repeatedly doing it at site and downloading pictures to get them done at site. Most of the eco-friendly green ideas have evolved by questioning and exploring; trail and error; and of course, by experimenting. The logic of these solutions may not be found in the internet and what is found there may not be applicable to a specific project.

Today, increased numbers of owners have greater creative urges than ever in the past, for the idea of a building is no more casual construction. There are numerous new ideas, which need newer methods to ensure their implementation, including a new kind of team spirit. No wonder, India is going though a turning point in green designs and eco-friendly architecture.